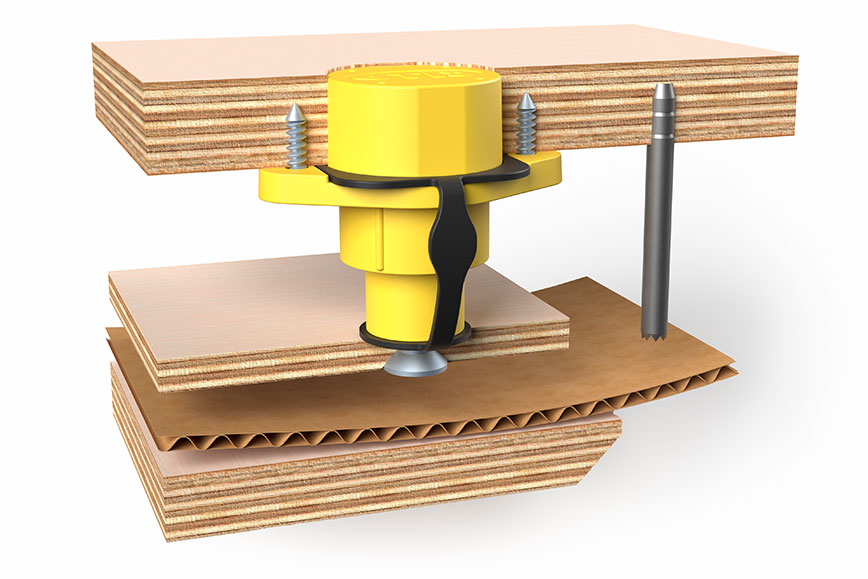

Specially designed for use in stripping tools with presser plate for the conversion of solid board and corrugated board

The CITO SECURE PRESSER 2.0 meets the highest requirements in the production process and sets new standards when it comes to safety, speed and efficiency.

The stripping component also impresses at extremely high machine speeds with fault-free and reliable production. The presser is completely preassembled with integrated screws and safety strap. This makes the installation of the presser between the upper stripping tool and the presser plate considerably faster and easier.

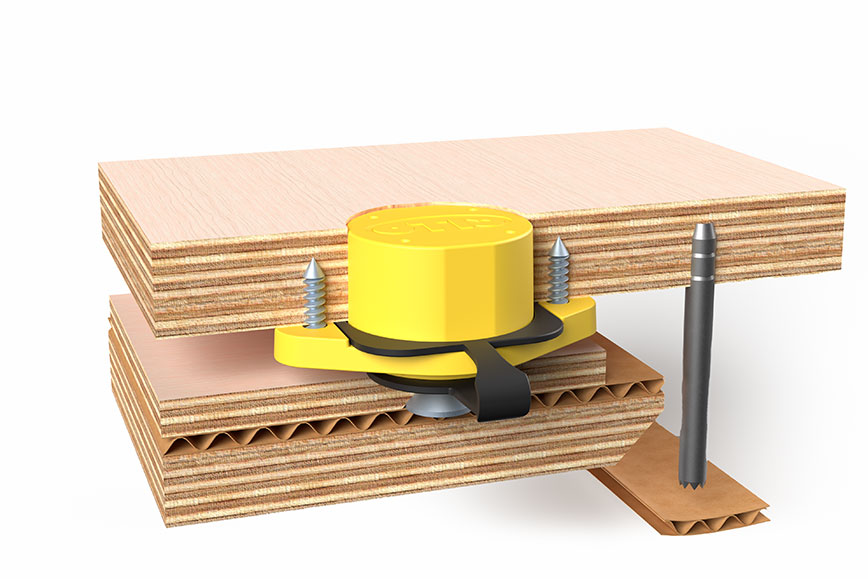

By using stripping tools with presser plate, a constantly high production performance can be achieved at maximum machine speed. The CITO SECURE PRESSER 2.0 is the key component, for ensuring uniform pressure distribution over the entire surface of the central stripping board. It does not matter whether low-quality material or sheets that do not lie flat are involved.

The CITO SECURE PRESSER 2.0 in combination with presser plate reduces machine stops and machine wear.

Your benefits

The advantages at a glance:

- Long service life for all types of jobs at full machine speed

- “Pick and place“: for quick and reliable assembly

- Safety strap and screws are completely preassembled

- Fast and secure screwing of the presser plate due to toothed anti-rotation protection

- Uniform pressure distribution even with challenging materials

- Fault-free production without interruptions

CITO SECURE PRESSER 2.0 – state-of-the-art stripping technology, which sets new standards when it comes to production reliability and efficiency!

Details

| Description | Colour | Unit | Order no. | |

|---|---|---|---|---|

| CITO SECURE PRESSER 2.0 completely preassembled with integrated screws and safety strap | Yellow | 50 pcs. | BLA02005 |

Installation

Download

Stand: 2024-08-14T19:01:13+02:00

Product leaflet

Cutting Geometries

Here you can download the template for the respective cutting geometry on a 1:1 scale.

Please ensure that the cutting contour is adjusted accordingly.